Manufacturing Industry News |

TMA President Steve Rauschenberger addresses mayors, village officials TMA President Steve Rauschenberger addresses mayors, village officials TMA’s Manufacturing Matters for Mayors Breakfast was a Collaborative Discussion on the Industry, Jobs, and Local Economies Post-Pandemic SCHAUMBURG, IL – Nearly 25 local municipal leaders and manufacturing executives met at the Technology & Manufacturing Association (TMA) for the 3rd Annual Manufacturing Matters for Mayors Breakfast, a collaborative discussion to explore how our local leaders and manufacturers can work together to improve our communities and strengthen our workforce. “This discussion between the manufacturers and local leaders here today is so important because when you boil it down, we all want the same thing: lower taxes for our local businesses, more high-paying jobs for our communities, a career path for students that includes high-tech manufacturing training, and a chance to produce goods and create an economic hub right here in the true manufacturing heartland of America,” said TMA President Steve Rauschenberger. “But state lawmakers are making it even more difficult for our manufacturers to be competitive and succeed. Local mayors know as well as we do what the higher taxes and anti-business legislation from Springfield means for our communities, but if we can work together with our municipal leaders, we can influence real, positive change.” Manufacturing plays a vital role in our local economies. In fact, the Chicagoland area contains 5 of the 10 largest manufacturing zip codes in the United States. Because of this, TMA brought our manufacturing community and our local leaders together so they could foster a more impactful relationship and pursue solutions for their shared local interests and issues. Especially now, it’s important that our local leaders and manufacturers collaborate as we recover from the COVID-19 pandemic, when many manufacturers are trying to get back on their feet and put their employees – and local residents – back to work. TMA’s event was also an opportunity for local leaders to meet newly elected mayors from April. Mayors and/or representatives from Addison, Alsip, Broadview, Cary, Elgin, Franklin Park, Hampshire, Hoffman Estates, Maywood, Orland Park, Park Forest, Roselle, Schaumburg, and Schiller Park were in attendance. After the discussion, the mayors and representatives toured TMA’s state-of-the-art manufacturing training facilities. “As a mayor and a small business owner, I understand the challenges TMA members face daily as they try to conduct business and help their employees grow in this difficult climate,” said Cary Mayor Mark Kownick, who also serves on the Executive Board of the Metropolitan Mayors Caucus. “Municipal government and manufacturers have similar interests – to grow jobs and create great places to live and work in their communities. I look forward to continue building relationships with TMA members as we pursue this mission on behalf of our residents.”

0 Comments

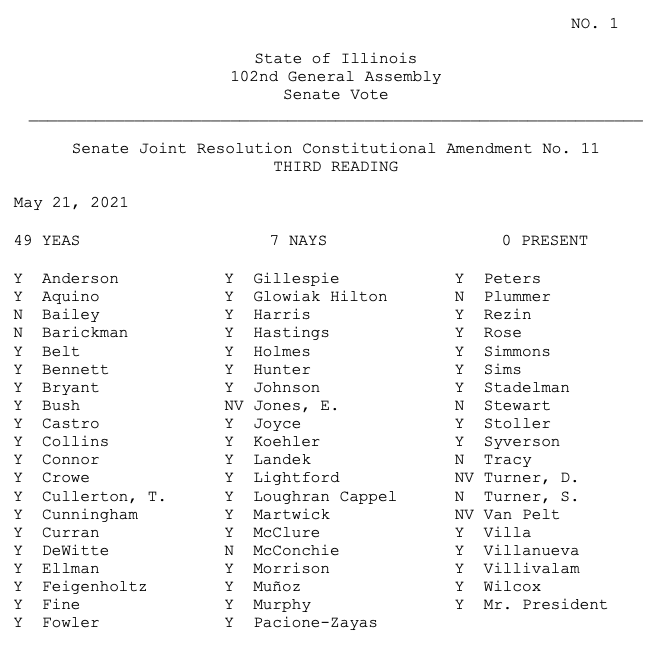

Apprentices Graduated with Nationally Recognized Manufacturing Certificates in Mold Making, CNC Programming, and Tool & Die Making SCHAUMBURG, IL – Manufacturers from all around the United States are concerned about the future of the industry as a retiring “Silver Tsunami” looms on the horizon – threatening a whole generation of the US manufacturers. For several years, the Technology & Manufacturing Association has been working with members, local high schools and community colleges to thwart the impending workforce disaster by offering training and education that equips their graduates with what many call “the gold standard” for manufacturing job training programs – and all completely debt-free. Thursday evening, TMA hosted their annual Related Theory Graduation and presented diplomas of completion in Tool & Die, Mold Making and CNC Machining to 38 students that have completed three long years of training and education in those particular fields. This year’s Graduation can be viewed HERE and HERE. “The COVID pandemic highlighted the critical importance of manufacturers and having a ‘made-in-America’ supply chain. The programs that educated these students over the last three years are the gold standard of manufacturing training. This nationally-recognized certificate, which requires over 500 hours of instruction and 6,000 hours of on-the-job training, will allow these students to enter into a lucrative and rewarding career in manufacturing,” said TMA President Steve Rauschenberger. Traditionally, TMA holds a public ceremony providing family, friends, and leaders in the manufacturing community the opportunity to honor both the graduating students and the employers that funded the students’ training and education. Commenting on the pandemic-related adversity the program’s staff and students overcame, Patrick Osborne, TMA’s Executive Vice President said, “I don’t think anyone could have foreseen a health emergency of this magnitude. I am especially proud of the fact that our TMA team, like our members, are among the most innovative people in the world, and we were able to continue these very important education programs during this unprecedented time.” TMA’s Related Theory Graduation is for students who have completed the three-year Apprentice Training Program. During their first year, they learn basic skills such as shop math, blueprint reading, and the basics of machine tool technology. In their second year, students begin their discipline in mold making, CNC programming, or tool & die. In the third year, students continue their education with more advanced training. The TMA Related Theory Apprenticeship Training Program has been assisting member companies in training their apprentices for over 70 years. Click here for more information on TMA's training programs. About TMA: Founded in 1925, the Technology & Manufacturing Association (TMA) represents and supports manufacturers in the Chicago metropolitan area and surrounding counties in northern Illinois, northern Indiana, and southern Wisconsin. TMA has almost 1,000 members and represents over 32,000 employees and nearly 26M square feet of manufacturing in Illinois.  29th Annual Event Encouraged Students to Pursue High-Tech Manufacturing Jobs SCHAUMBURG, IL – Over 50 students from nine northern Illinois high schools competed again this year in the Technology & Manufacturing Association’s (TMA) 29th annual Precision Machining Competition. The annual contest encourages students to pursue high-skill, high-paying, high-demand careers in advanced manufacturing. Awards were presented May 13th on TMA social media HERE and HERE. Even with the COVID-19 restrictions that this year’s participating schools had to fight through, many students remained focused on competing to help advance their careers in the manufacturing and technology fields to further equip them with the skills to produce goods for people around the country and world. Emblematic of the manufacturing sector’s perseverance during the pandemic, these hard-working students created more than 65 projects showcasing their skills in CAD design, sine bar, grinding vice, CNC turning, CNC milling, CNC CAM, CNC programming, and other abilities and techniques essential to modern machining. Participants in these manufacturing activities for high school students included Cary-Grove, Hampshire, Jefferson (Rockford), Lake Park, McHenry East, McHenry West, first-time competitor Ridgewood, Streamwood, and Wheeling. Students heard remarks from Leigh Coglianese, TMA Manager of Training & Education, April Senase, West CTE Manufacturing Teacher, and Tom Cicardo, Tooling Apprentice, Matrix Tool. The students also had the opportunity to connect with local manufacturers and learn more about possible careers. “This year’s Precision Machining Competition is a testament to the indomitable spirit of these young people,” said TMA President Steve Rauschenberger. “In a year marked by uncertainty and adversity, these students persevered, overcoming numerous obstacles to create the impressive projects we saw here today. It’s rewarding for our association to know these students will have the opportunity to obtain high-paying and high in-demand jobs in manufacturing.” The Precision Machining Competition is not only one of TMA’s most effective initiatives for career recruitment into precision metalworking, but one of its most important as well: experts estimate the next decade will see the creation of about 3.5 million new manufacturing jobs. Unfortunately, a precision metalworking “skills gap” means that well over half of those jobs—as many as two million—could go unfilled. Initiatives like the Precision Machining Competition highlight the demand for technology and precision manufacturing skills in today’s workforce. The Competition also celebrates the inventive students who will be the ones to help us close that skills gap in the years to come. “These students are the workforce of the future,” noted Coglianese. “They’ll have the opportunity to fill one of the thousands of open jobs nationwide in high-tech, high-wage manufacturing roles, setting themselves up for lifelong career success in an exciting, dynamic field.”  TMA is mentioned in below Illinois Review.com story: SPRINGFIELD - Private and public sector unions will rule the state of Illinois with a constitutional amendment that passed the Illinois Senate Friday afternoon. Eleven (11) Republican senators and all voting Democrats supported the measure that would ban any "right to work" effort in Illinois. Three Republican senators were in such strong support of banning right to work in Illinois, they co-sponsored the measure: Senator Neil Anderson of Moline; Donald DeWitte of Dundee: and John Curran of Lemont. Here's what a Wirepoints commentary says about Senate Joint Resolution Constitutional Amendment 11 : ... The amendment, if passed by three-fifths votes in each chamber and approved by voters, would prohibit municipalities and the state from ever taking any measure that would impair the ability of workers to collectively bargain over wages, hours, terms and conditions. In other words, it would constitutionally ban any attempt to reform collective bargaining rules for both public and private unions. The resolutions, including links to the text, are here and here. The amendment would also effectively ban any right-to-work movement. SJRCA 11, analysts say, adds to the Bill of Rights Article of the Illinois Constitution that employees shall have the fundamental right to organize and to bargain collectively through representatives of their own choosing for the purpose of negotiating wages, hours, and working conditions, and to protect their economic welfare and safety at work. It prohibits any law state or local that interferes with, negates, or diminishes the right of employees to organize and bargain collectively over their wages, hours, and other terms and conditions of employment and workplace safety, including any law or ordinance that prohibits the execution or application of agreements between employers and labor organizations that represent employees requiring membership in an organization as a condition of employment. That means, observers say, requiring union membership and the fees, expenses, etc., unions require cannot be stifled in anyway - such as any effort that would give workers the right to choose whether they want to be union members. Groups that signed on in opposition to the measure include the Technology & Manufacturing Association, the Illinois Municipal League and 120 other business groups. Their cautions were ignored and there was no opposition voiced during the Senate floor debate. Below is the roll call for Friday's vote. The 11 Republican senators joined the Democrat super-majority in voting yes are Anderson; Bryant; Curran; DeWitte; Fowler; McClure; Rezin; Rose; Stoller; Syverson and Wilcox. The measure will now go to the Illinois House. If it passes there, the question of whether or not to amend the Illinois Constitution in such a way will be on the 2022 Illinois General Election ballot.  From The Economist:

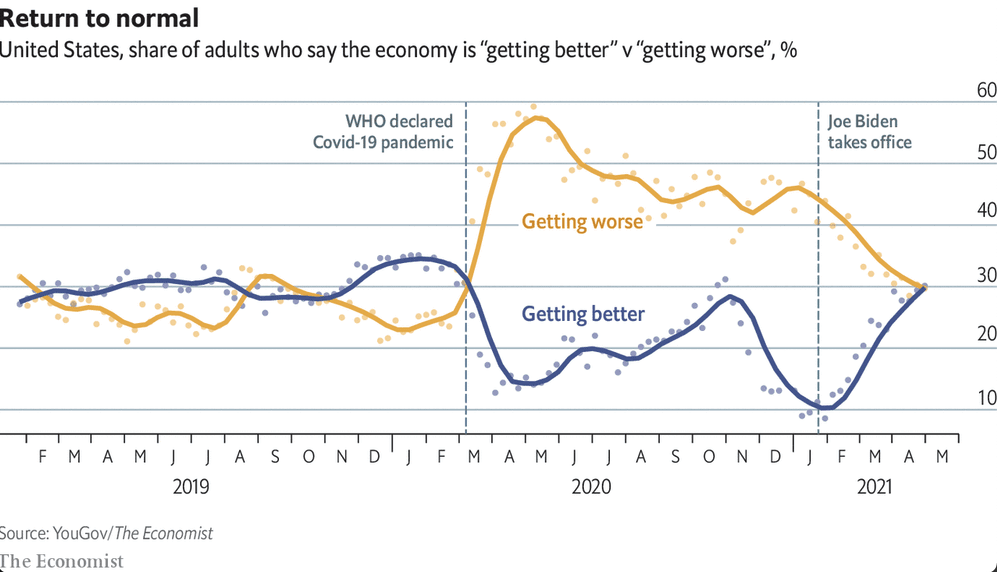

A poll released on May 5th by YouGov in partnership with The Economist shows that, for the first time since the coronavirus pandemic began, Americans are split on whether the economy is on the rise or in decline. The survey, conducted between May 1st and May 4th, asked 1,500 American adults, “Overall, do you think the economy is getting better or worse?” Roughly 30% said the economy was on the upswing, 30% said it was trending downwards and 28% said it was about the same. All are within each other’s margin of error. Read more HERE.  In their May 11, 2021 update story, ZDNet.com offers information about the Colonial Pipeline cyber attack in response to these questions: 1. What is Colonial Pipeline? 2. How did the Colonial Pipeline ransomware attack happen? 3. Why does the Colonial Pipeline ransomware attack matter? 4. Will there be gas shortages? 5. Have any agencies become involved? 6. Who is DarkSide? 7. What happens next? Get the answers HERE: A coating of zinc the thickness of a sheet of paper can protect a steel structure for 100 years. Galvanized coating is one of the most durable methods of protecting against corrosion that is currently available.

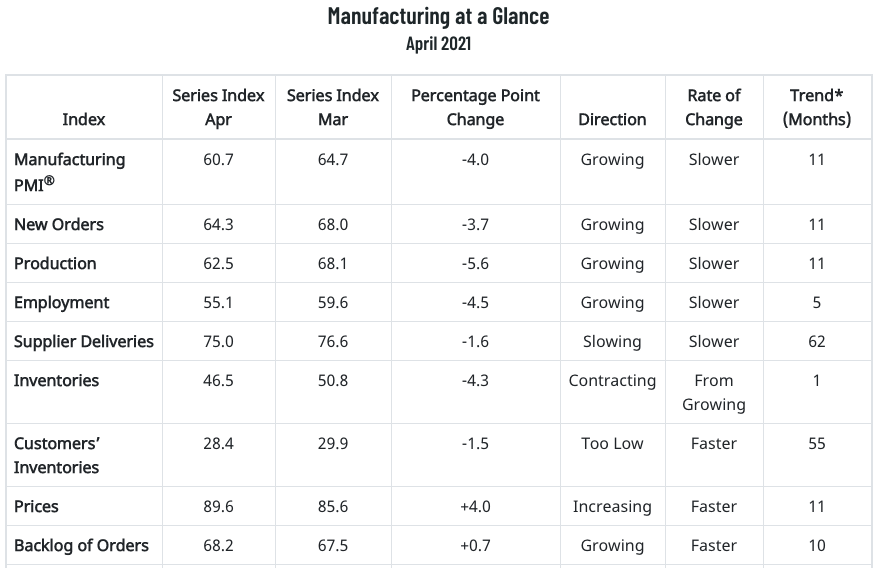

That’s what Gatto Industrial Platers, Inc. offers, and what George Gatto Jr oversees every day. George Gatto Jr grew up around his family’s business, but spent ten years in real estate before accepting his father’s standing invitation to join Gatto Industrial Platers. During his teen years, George Jr worked summers at the family business – which led him to believe that particular work just wasn’t for him. “I’d spend 10 hours a day working and would go home exhausted, hot and dirty. Making something like $4.50 an hour, before taxes, as a teenager, I decided I’d do better mowing lawns,” he said. “A friend and I started mowing and made more money. That started me thinking about college and what career I’d work in.” Gatto studied advertising and marketing at Drake University, and headed into the real estate industry directly after graduating in 2002 – the very field of work that eventually led the Gatto Family into manufacturing. The older George Gatto was operating a machine shop when the opportunity came up to purchase a plating business in Chicago. Gatto – a tool & die maker himself – had started a small machining business making motorcycle forks. “He also got into making other things like the polished and plated poles to which velvet ropes for crowd control are attached. Soon he was making different furniture components, and learned how important plating was to each of them,” Gatto Jr. said. “My dad would go to the plants where they were plating and watch how it was done. The process looked productive, so when the opportunity came up for him to buy a plating company, he did.” The plating business seller was a member of the Gatto extended family, so Gatto Sr’s father came on to help the effort and ended up staying involved until he was 95 years old, just before passing away in 2018. In the meantime, the younger George Gatto Jr said he was struggling in a very difficult real estate market during the 2008 economic recession and its aftermath. One day, he accepted his dad’s invitation to join him at a lecture series hosted by the Technology & Manufacturing Association. During the dinner conversation, other TMA members began asking George Jr why he continued in the struggling real estate industry when his father was nearing retirement age – and would soon be taking his industry knowledge with him. “My dad was thinking about what his future was, so these guys heard this for awhile from my dad. They said to me, ‘Listen, you know you’re at a perfect point your life where you know you’ve been out working, and you’ve got maybe a five year window if you want to do this,’” Gatto Jr said. “’It’s going to be gone, they said, and you would have passed up a good opportunity.’” The next day after the TMA event, George Jr picked up the phone and shocked his father by suggesting they have a conversation about him joining the company. That was over ten years ago. Now George Gatto Jr is president of Gatto Plating and is serving on the Technology & Manufacturing Association’s Board of Directors. Gatto Industrial Platers, Inc. has grown exponentially in shop floor size and number of employees. The company moved from a 30,000 square foot two-story building in Chicago to another building they expanded to 200,000 square feet. There are currently 150 employed. During the COVID crisis, Gatto Industrial Platers fared well, George Jr said. Zinc plating is used in nearly all industries – from medical equipment to household appliances , automotive, heavy equipment to railroad needs. “Our sales were down, but we didn’t have to think about shutting down or doing anything like that. We did reduce hours and took a hit to sales in the second quarter,” Gatto said. “But we are coming through in good shape.” Gatto, 41, says his biggest personal challenge these days as president of Gatto Industrial Platers, Inc. is managing his time. He’s busy every day answering business questions, coming up with industry solutions and strategizing the company’s future – but he also has young family demands. The Gattos have three boys – ages five, three and one. The pressures mounted during COVID as his wife pushed ahead in her career while together they juggled childcare. Assistance via email from the Technology & Manufacturing Association was especially appreciated during the early days of the COVID crisis, he said. It helped keep the company’s decision-makers informed as to what state and federal government were doing while team members dealt directly with personnel issues that had never been an issue previously – and helped to answer crucial questions few had time to find on their own. Being a part of a trusted association network before crises erupted proved to be especially valuable during those early COVID days, he said. “TMA provided information about what was going on, and what others were doing in these situations. We could take ideas from what everybody else said, and apply that to what worked for us, like where to get needed supplies. That part of TMA is extremely valuable because you build those relationships in a time when you don’t you know necessarily need them, but they’re there when you do need them.” Gatto says he’s hoping to lead the business to double within the next five to 10 years – and that he will be counting on his involvement with fellow manufacturers in TMA to help him achieve that goal. “We have the infrastructure to grow that much. I’m interested in developing the technology here over the next few years, and I’ll be looking to others in TMA for ideas on how they’ve updated their companies’ equipment,” he said. While he may not be able to get as involved in TMA Young Leader activities as he was before his three sons came along, Gatto says he plans to continue to be involved in the TMA board for the next few of years. “I know firsthand how important TMA networking can be,” he said. “It changed my career path – something I never expected to happen.” More information about Gatto Industrial Platers, Inc is available at www.gattoplaters.com. The company is located at 4620 W. Roosevelt Road in Chicago. From TMA's March/April 2021 News Bulletin. Profile and photo by Fran Eaton.  (Tempe, Arizona) — Economic activity in the manufacturing sector grew in April, with the overall economy notching an 11th consecutive month of growth, say the nation's supply executives in the latest Manufacturing ISM® Report On Business®. The report was issued today by Timothy R. Fiore, CPSM, C.P.M., Chair of the Institute for Supply Management® (ISM®) Manufacturing Business Survey Committee: “The April Manufacturing PMI® registered 60.7 percent, a decrease of 4 percentage points from the March reading of 64.7 percent. This figure indicates expansion in the overall economy for the 11th month in a row after contraction in April 2020. The New Orders Index registered 64.3 percent, declining 3.7 percentage points from the March reading of 68 percent. The Production Index registered 62.5 percent, a decrease of 5.6 percentage points compared to the March reading of 68.1 percent. The Backlog of Orders Index registered 68.2 percent, 0.7 percentage point higher compared to the March reading of 67.5 percent. The Employment Index registered 55.1 percent, 4.5 percentage points lower than the March reading of 59.6 percent. The Supplier Deliveries Index registered 75 percent, down 1.6 percentage points from the March figure of 76.6 percent. The Inventories Index registered 46.5 percent, 4.3 percentage points lower than the March reading of 50.8 percent. The Prices Index registered 89.6 percent, up 4 percentage points compared to the March reading of 85.6 percent. The New Export Orders Index registered 54.9 percent, an increase of 0.4 percentage point compared to the March reading of 54.5 percent. The Imports Index registered 52.2 percent, a 4.5-percentage point decrease from the March reading of 56.7 percent.” Fiore continues, “The manufacturing economy continued expansion in April. Survey Committee Members reported that their companies and suppliers continue to struggle to meet increasing rates of demand due to coronavirus (COVID-19) impacts limiting availability of parts and materials. Recent record-long lead times, wide-scale shortages of critical basic materials, rising commodities prices and difficulties in transporting products are continuing to affect all segments of the manufacturing economy. Worker absenteeism, short-term shutdowns due to part shortages, and difficulties in filling open positions continue to be issues that limit manufacturing-growth potential. Optimistic panel sentiment increased, with 11 positive comments for every cautious comment, compared to an 8-to-1 ratio in March. Demand expanded, with the (1) New Orders Index growing at a strong level, supported by the New Export Orders Index continuing to expand, (2) Customers’ Inventories Index hitting another all-time low and (3) Backlog of Orders Index continuing at a record-high level. Consumption (measured by the Production and Employment indexes) indicated some cooling, posting a combined 10.1-percentage point decrease to the Manufacturing PMI® calculation. All top six industries reported moderate to strong consumption expansion. The Employment Index expanded for the fifth straight month, but panelists continue to note significant difficulties in attracting and retaining labor at their companies’ and suppliers’ facilities. Inputs — expressed as supplier deliveries, inventories, and imports — continued to support input-driven constraints to production expansion, at lower rates compared to March, due to an undesired inventory draw down. Inputs negatively contributed to the PMI® calculation, by a combined 5.9 percentage points. The importation of items marginally slowed in the period, driven by port backlogs. The Prices Index expanded for the 11th consecutive month, indicating continued supplier pricing power and scarcity of supply chain goods. “All of the six biggest manufacturing industries — Fabricated Metal Products; Chemical Products; Food, Beverage & Tobacco Products; Computer & Electronic Products; Transportation Equipment; and Petroleum & Coal Products, in that order — registered moderate to strong growth in April. “Manufacturing performed well for the 11th straight month, with demand, consumption and inputs registering strong growth compared to March. Labor-market difficulties at panelists’ companies and their suppliers persist. End-user lead times (for refilling customers’ inventories) are extending. This is due to very high demand and output restrictions, as supply chains continue to respond to strong demand amid COVID-19 impacts,” says Fiore. All 18 manufacturing industries reported growth in April, in the following order: Electrical Equipment, Appliances & Components; Textile Mills; Furniture & Related Products; Machinery; Fabricated Metal Products; Primary Metals; Miscellaneous Manufacturing; Chemical Products; Plastics & Rubber Products; Food, Beverage & Tobacco Products; Computer & Electronic Products; Nonmetallic Mineral Products; Apparel, Leather & Allied Products; Transportation Equipment; Paper Products; Petroleum & Coal Products; Printing & Related Support Activities; and Wood Products. WHAT RESPONDENTS ARE SAYING

More HERE |

AuthorManufacturing industry news is provided by the Technology & Manufacturing Association in Schaumburg, IL Archives

June 2024

Categories |

RSS Feed

RSS Feed